Improving print quality worldwide !

Flexo Wash is a leading cleaning solutions company based in Denmark. We specialize in cleaning equipment and eco-friendly cleaning liquids for the flexographic and converting industries. The mission of Flexo Wash is to successfully develop innovative and high-quality cleaning equipment to satisfy needs of printers worldwide and thus creating consistent print quality and high productivity with focus on safe working conditions and low impact on the environment.

Let us guide you on your journey towards higher print quality!

years developing innovative cleaning technology

+

Country Service

+

Machines Installed

+

Positive Reviews

%

Proper cleaning is vital for your business

Find the right solution for you

Liquid or laser cleaning?

ANILOX CLEANING WITH LIQUID

Daily deep cleaning of your aniloxes

The fully automatic anilox cleaners are designed to deep clean/restore anilox rolls or sleeves of all sizes. In other words, it is also a very good tool for the daily washing and maintenance of aniloxes.

ANILOX CLEANING WITH LASER

Waste-free & sustainable cleaning

Get a waste-free, completely safe, and automatic anilox cleaner that will give you a more sustainable cleaning solution. The FW LASER Anilox Cleaners can be installed without requiring water supply, drain or safety equipment.

LIQUIDS FOR ALL INK TYPES

Sustainable cleaning liquids

The Flexo Wash cleaning liquids are of high durability and formulated for easy handling, trouble-free operation, and long service intervals. This makes sustainable cleaning liquids an affordable alternative to solvents, thus providing a safer cleaning of press parts and a cleaner environment.

Very best opinions

Meet our Customers

"Because of the anilox cleaner the condition of our aniloxes is always consistent. It is important to always have clean aniloxes to keep the same printing quality. And that we have!"

Ulrich Wiemers

Coveris Flexibles

"The unit has made a terrific difference to the cleaning regime and has achieved great results!"

Phillip Taylor

Franklin Web

"Previously 12-15 plates were damaged each week, this figure is now one or two, and those are not caused by cleaning."

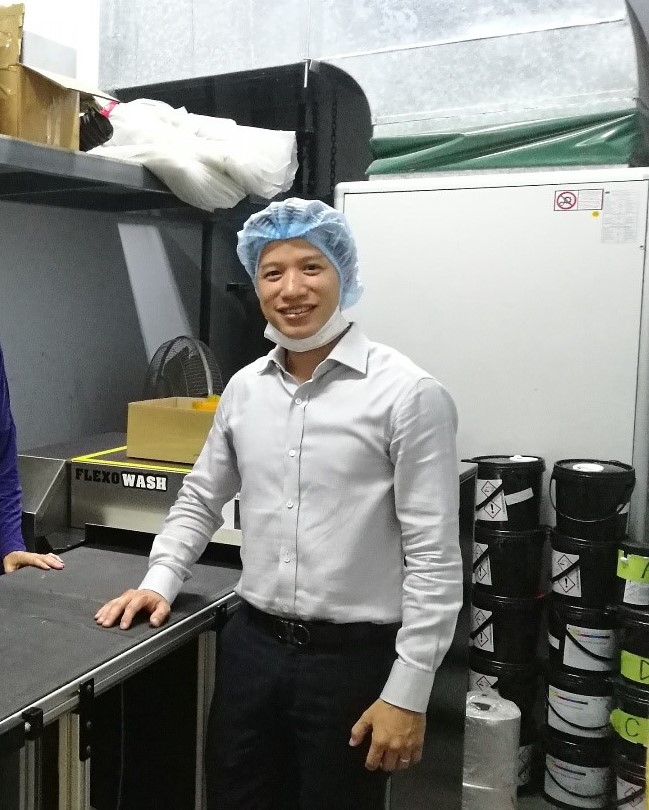

Piyapong Wongvorakul

Trisan

Contact Us

Headquarter

Flexowash ApS

Grenaavej 631K

DK-8541 Skoedstrup, Denmark

VAT no. DK15383348

VAT no. DK15383348

+45 8699 3631

MALAYSIA OFFICE

Flexowash Asia Sdn Bhd

No. 6, Jalan Meranti Jaya 11,

Meranti Jaya Industrial Park,

47100 Puchong, Selangor, Malaysia

flexowashasia@gmail.com

Tel: (60) 8060 8286

Fax:(60) 8060 6286

Connect

[wpforms id="9481"]